Description:

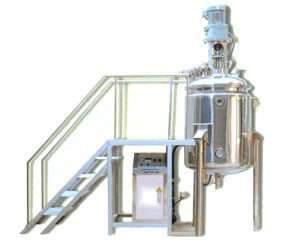

Softgel Mixer , Soft gel Manufacturing Plant, gelatin manufacturing plant, softgel gelatin capsule manufacturing process adopts advanced technology to blend and mix color according to characteristics of the gelatin. The system consists of hydraulic lifter, stirring blender and frequency control system.

The gelatin melting tanks are designed and manufactured based on the gelatin melting process and gelatin property. Three-layers structure is traditional design, which is very helpful to ensure a even heating and working efficient. During whole production activity, cGMP and FDA guideline is followed from design to material and making. It is very popular in the pharmacy, health care, paintball,cosmetics and food industry.

Operation procedure: insert the stirring blender vertically into the container's eccentric position with a depth 1/3 of the liquid level from the container bottom, and leave enough clearance on the bottom for materials to flow freely.

Features of Softgel Mixer, Soft Gel Manufacturing Plant:

Easy operation, good color mixing effect, stable mechanical performance, high production efficiency, being easy for disassembling, assembling, cleaning and so on. Designed with a stirring blender which removes air bubbles in the medium through the special guide holes and grooves of guide cylinder. It is put into the glue barrel by hydraulic lifter (hydraulic lifter can make striing blender stay on any position for operation) or by automatic control unit so that stirring blender can rotate up and down automatically in the glue.

The gelatin melting tanks are designed and manufactured based on the gelatin melting process and gelatin property. Three-layers structure is traditional design, which is very helpful to ensure a even heating and working efficient. During whole production activity, cGMP and FDA guideline is followed from design to material and making. It is very popular in the pharmacy, health care, paintball,cosmetics and food industry.

Automatic Gelatin mixing System - Softgel Mixer , Soft gel Manufacturing Plant

gelatin melting Mixer . All the operation step can be controlled by PLC and HMI operating system.

Technical Parameters of Softgel Mixer , Soft gel Manufacturing Plant:

| Technical Specification | Soft gel Mixer-600 |

Soft gel Mixer-800 |

Soft gel Mixer-1000 |

Valid capability |

150L~600L |

200~800L |

300~1000L |

Vacuum Degree |

0.02~0.09Mpa |

0.02~0.09Mpa |

0.02~0.09Mpa |

Structure |

Jacketed Stainless Steel Tank with Insulation (Hot Water/Oil Circulation) |

||

Working Temperature |

0~120℃ |

0~120℃ |

0~120℃ |

Power |

5.5KW |

7.5KW |

7.8KW |

Mixing Speed |

0~35RPM |

0~35RPM |

0~35RPM |

Heating Area |

4.0 m2 |

4.8 m2 |

5.2 m2 |

Dimension |

Φ1100mmx2120 mm |

Φ1200mmx2220 mm |

Φ1300mmx2340 mm |

Weight |

650KG |

750KG |

950KG |

Jacket Work Pressure |

Atmospheric |

Atmospheric |

Atmospheric |

Surface |

Mirror/Matte Polish |

Mirror/Matte Polish |

Mirror/Matte Polish |

Mixing Type |

Paddle+Wall Scraper |

Paddle+Wall Scraper |

Paddle+Wall Scraper |

Equipment installed |

Vacuum Meter; Temperature Meter; Pressure Gage;Manhole;Lamp;Air Vent |

||

Electric Voltage |

380V;240V;220V; 50HZ; 60HZ (Customized) |

||

Note |

Modification is available based on specific requirement |

||

Features: